Solar MLPE hacks for the installer edge

Time is money. We’ve all heard the age-old adage, but if you’re a solar installation company, it absolutely rings true: time is your worst enemy. Labor is expensive, so the longer a project takes, the more it costs an installer to put in a solar system, and it comes right out of their bottom line. Non-hardware costs such as installation labor, permitting fees and interconnection costs are referred to as “soft costs.” According to the U.S. Department of Energy, these soft or “plug-in” costs of solar account for as much as 64% of the total cost of a new solar system, and labor is one of the largest culprits. It’s no surprise that solar installers are looking for ways to reduce these costs, and any tool or trick they can employ to speed a project along may just give them the edge they need to not only survive in this highly competitive industry, but to thrive.

Time is money. We’ve all heard the age-old adage, but if you’re a solar installation company, it absolutely rings true: time is your worst enemy. Labor is expensive, so the longer a project takes, the more it costs an installer to put in a solar system, and it comes right out of their bottom line. Non-hardware costs such as installation labor, permitting fees and interconnection costs are referred to as “soft costs.” According to the U.S. Department of Energy, these soft or “plug-in” costs of solar account for as much as 64% of the total cost of a new solar system, and labor is one of the largest culprits. It’s no surprise that solar installers are looking for ways to reduce these costs, and any tool or trick they can employ to speed a project along may just give them the edge they need to not only survive in this highly competitive industry, but to thrive.

One challenge in this effort to reduce labor costs, is the growth in utilization of module-level power electronics (MLPEs) such as microinverters and DC optimizers. Unlike string inverters which, for residential applications, typically mean a single string inverter is serving all the PV modules on the roof, each MLPE is typically serving a single module. Although an MLPE solar system is often more expensive in initial capital costs and more labor-intensive to install compared with string inverters, it also has a better levelized cost of energy (LCOE) over string inverters as MLPE systems produce more energy over the life of system. It makes sense, then, why MLPE systems comprised 62% of the U.S. residential solar market in 2015, according to GTM Research, and the market isn’t done there as MLPE is predicted to be the fastest-growing product segment over the next five years.

Installers are feeling the time crunch and the challenge today is even greater to take a high-demand yet labor-intensive product and still perform a profitable installation. Let’s take a look at a few ways to streamline the MLPE installation process with some serious solar hacks.

TIME-SAVING PRODUCTS

TIME-SAVING PRODUCTS

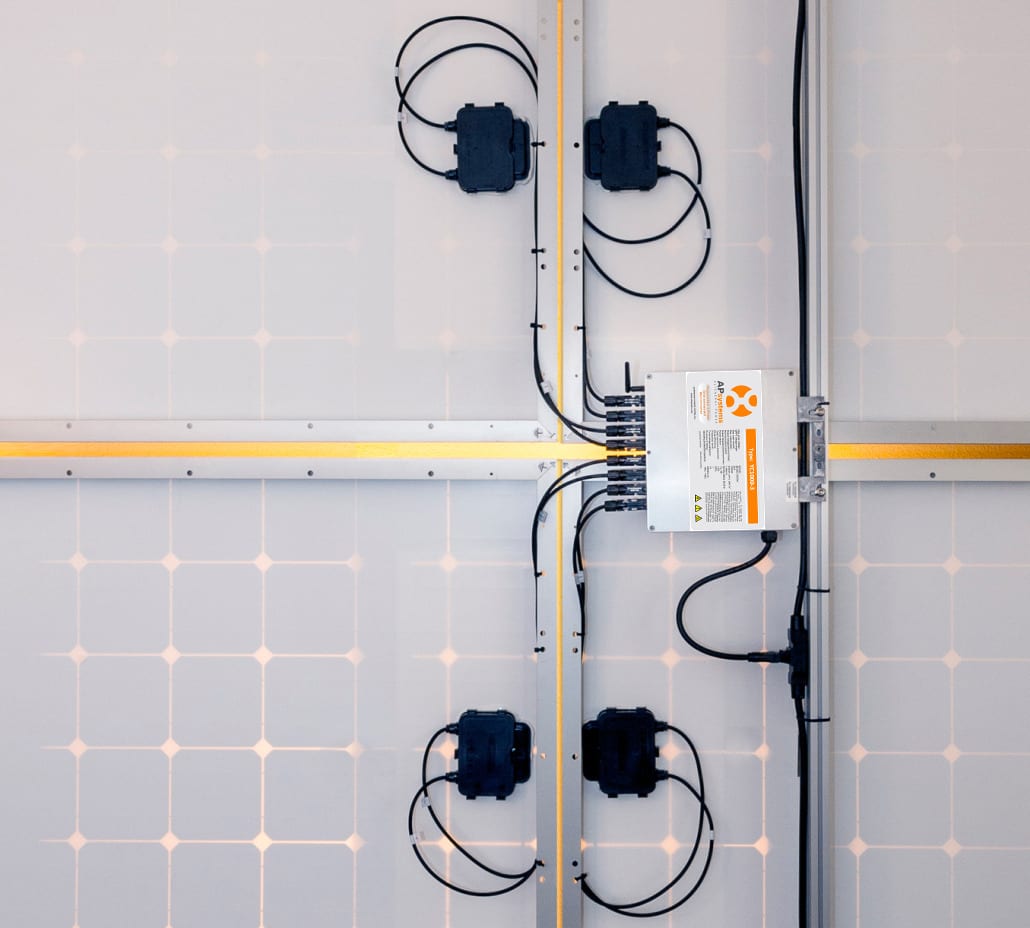

Microinverters which serve multiple modules exist today and with 2-to-1 and even 4-to-1 module to microinverter options available, homeowners can still get the benefits of an MLPE systems with independent MPPT per module, while installers cleverly reduce the amount of units they’re having to put on the roof by 50% to 75%.

MLPE ARCHITECTURE

Most MLPE systems utilize a trunk bus cable to which installers then attach every microinverter. Not only are trunk cables an expensive part of the system, but placing it on the roof and securing the cable to the racking takes time. Products, such as the APsystems YC500A, utilize a daisy-chain method of cabling and do away with the trunk cable. What’s more, the daisy chain is pre-integrated into the unit so it comes completely pre-cabled and ready to go.

FREE TRAINING

FREE TRAINING

Most solar equipment manufacturers offer free training webinars and videos on their products anymore so absolutely take advantage of this. Don’t miss out on the time (and money) saving tips you can pick up in a short training course or online video series.

GATEWAY SET-UP

The gateway communication unit for microinverter installations can be a breeze if installers follow a few simple tips for commissioning the system. Connect the gateway to the internet via a standard Ethernet cable so it can download the most current firmware before you begin to commission the system. Ideally, you’ll want to do this after the inverter installation but before module installation so the unit can update while your team puts panels on the roof so you don’t lose time. Be sure to connect cables in the right order as some gateways may take longer if power is applied before the network cable (unless the system will be connected via Wi-Fi). Obtaining the homeowner’s Wi-Fi network information and password before hitting the jobsite will also save you time in connecting the gateway.

TIME-SAVING APPS

There are some amazing apps out there for solar installers that can help installers streamline system setup. ArrayApp by APsystems, for example, allows installers to create the homeowner account for online monitoring, scan units directly without having to wait for up to 30 minutes for auto-detection of the inverters and create the array site map all from their mobile phone or tablet. Simply search for ArrayApp on your iPhone App Store or Google Play for Android devices.

Taking advantage of these time-saving measures can save an installer money but also help them get more installations completed in a single day. As the solar industry continues to lean heavily toward MLPE systems, finding ways to install faster and more effectively can mean the difference between a profitable operation and one that struggles to be competitive. Be sure to do your research, training, find out what other installers are doing and build your own list of valuable solar installation hacks.